Proper packaging is crucial for the safety and sterility of medical devices. A medical heat sealer plays a crucial role in ensuring this. It creates a secure seal that protects medical devices from contamination, damage, and environmental factors. By using controlled heat, pressure, and time, these sealers help maintain the sterility of medical equipment until it is used, ensuring patient safety.

What Are Medical Heat Sealers?

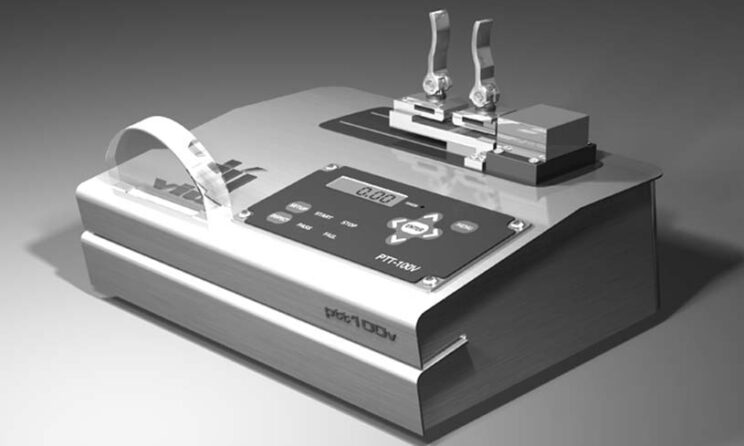

A medical heat sealer is designed to seal medical device packaging, such as pouches, trays, and bags. It applies heat and pressure to bond materials like plastic or foil, ensuring a strong, airtight seal. These machines are essential in healthcare settings to keep devices sterile and free from contaminants, making them ready for safe usage in critical medical procedures.

Why Is Packaging Safety Crucial in Healthcare?

Packaging safety is vital to maintain the sterility of medical devices and prevent contamination. Any breach in packaging can expose devices to harmful bacteria, dust, or moisture. A medical heat sealer creates a seal that withstands transportation and storage challenges, keeping devices intact. Safe packaging ensures that medical tools remain effective, reducing risks to patient health during surgeries or treatments.

How Does a Medical Heat Sealer Work?

A medical heat sealer applies heat and pressure to bond materials securely. Operators can adjust temperature, pressure, and sealing time to match specific packaging requirements. This precision ensures the seal is strong, durable, and compliant with healthcare standards like ISO 11607. Reliable sealing minimizes contamination risks, making these machines indispensable in the healthcare industry.

Features That Enhance Medical Heat Sealers’ Performance

Medical heat sealers have advanced features to ensure precise and consistent sealing. Temperature control mechanisms allow for accurate heating, preventing weak seals. Pressure adjustment ensures an even bond across the packaging material. Additionally, monitoring and validation systems verify that every seal meets stringent safety requirements, ensuring the packaging remains intact during storage and transport.

Applications of Medical Heat Sealers in Device Packaging

Medical heat sealers package a variety of medical devices, including surgical instruments, implants, and syringes. These versatile machines handle different packaging types, such as flexible pouches, rigid trays, and sterilization wraps. By maintaining sterility and integrity, they are critical in hospitals, clinics, and manufacturing facilities, ensuring medical devices are safe for patient use.

Why Choose a Reliable Medical Heat Sealer?

Investing in a reliable medical heat sealer ensures compliance with regulatory standards and patient safety. High-quality sealers reduce the chances of packaging failures, which can compromise device sterility. These machines deliver consistent results with features like real-time monitoring and precision controls. Choosing the right sealer is an important step in maintaining trust and reliability in healthcare packaging.

Conclusion

A medical heat sealer is a vital tool in ensuring the safety of medical devices. By providing strong, reliable seals, it protects devices from contamination and ensures sterility. These machines help healthcare providers meet safety standards and maintain patient trust. Their role in secure packaging highlights their importance in delivering safe and effective medical care.